Motor Efficiency Explained: Getting More Work from Less Energy

Discover how motor efficiency works, what IE ratings mean, and practical ways to cut losses, save energy, and get more output from every kilowatt.

Efficiency In Plain Terms: Motor efficiency expresses how effectively a motor turns electrical input into mechanical output. In simple terms, efficiency equals mechanical output power divided by electrical input power, with the difference lost as heat, vibration, and other losses. Output power relates to torque and speed, so a motor that delivers the required torque at the desired speed while drawing less input power is more efficient. Efficiency depends on how closely the motor operates to its optimal load point. Many motors have an efficiency sweet spot near moderate to high load, and they typically become less efficient when significantly underloaded. Understanding the duty cycle and variation in operating conditions helps you select and run a motor where it performs best. Better efficiency reduces energy consumption, lowers operating costs, and can extend equipment life by reducing heat stress. Getting more work from less energy starts with grasping this ratio and aiming to minimize every source of avoidable loss.

Where The Energy Goes: Losses inside motors come from several places, and controlling them is the key to higher efficiency. Copper losses occur when current flows through windings, creating I squared R heating that wastes energy. Core losses arise from alternating magnetic fields in the stator and rotor iron, driven by hysteresis and eddy currents. Mechanical losses include bearing friction and windage from the cooling fan. Additional stray load losses stem from leakage flux and manufacturing imperfections. Design choices mitigate these losses: high quality lamination steel reduces eddy currents, optimized slot fill cuts copper resistance, and precision bearings with proper lubrication lower friction. Right sized fans and effective cooling remove heat without excessive drag. Power quality matters too; voltage imbalance and harmonics elevate current and heating, degrading performance. By minimizing each category of loss through design, supply conditioning, and application practices, a motor delivers more usable torque per unit of energy absorbed from the grid.

Right Sizing And Control: Matching the motor to the load is one of the most powerful levers for efficiency. Oversized machines often run lightly loaded, where efficiency and power factor are poorer, while undersized units run hot and stressed. Select a motor with appropriate torque characteristics for the duty, considering starting demands, inertia, and the expected operating range. For variable torque applications such as fans and pumps, variable frequency drives (VFDs) can cut energy dramatically by reducing speed when full flow is not needed. The affinity laws show that power for these loads falls roughly with the cube of speed, so modest slowdowns yield big savings. For constant torque processes, VFDs improve control, reduce mechanical shock, and can optimize throughput with fewer losses. Soft starters help with gentle acceleration but do not deliver the same running energy reductions as true speed control. Evaluate couplings, gear ratios, or direct drive to avoid unnecessary transmission losses and keep the motor near its efficient operating zone.

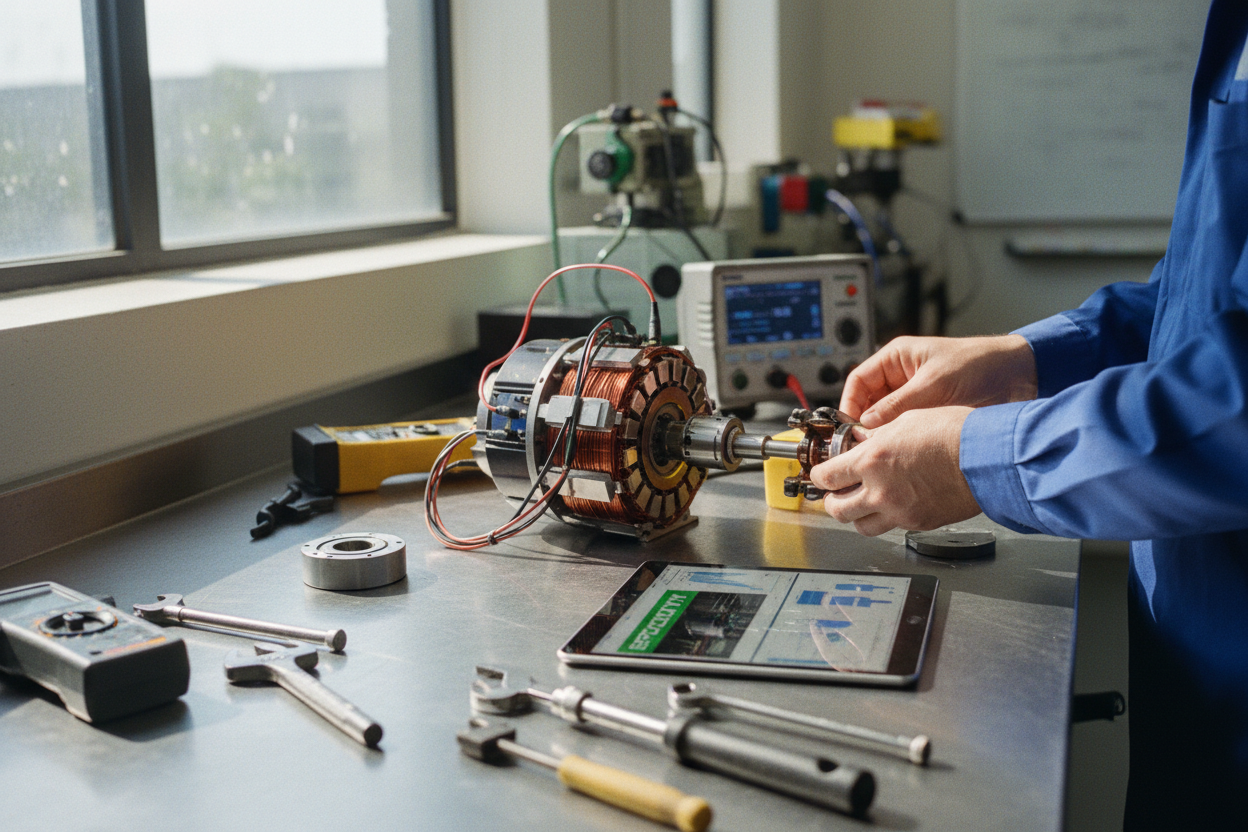

Installation And Care: Even a premium motor wastes energy if installed or maintained poorly. Proper alignment of shafts and couplings reduces mechanical losses and prevents bearing wear. Correct belt tension and pulley alignment avoid slip and friction that turn energy into heat. Ensure adequate ventilation and clean cooling paths so the motor can shed heat and maintain low resistance in windings. Use appropriately sized conductors and tight terminations to minimize voltage drop and extra I squared R losses in the supply circuit. Monitor phase balance on three phase systems; imbalance raises current and heat, cutting efficiency and reliability. Routine care matters: scheduled lubrication, vibration checks, and cleaning protect bearings and windings. Techniques like thermography, vibration analysis, and motor current signature analysis help detect emerging issues before they sap performance. When rewinding is needed, choose reputable methods that preserve slot fill and magnetic integrity, since poor rewinds can permanently reduce efficiency. A disciplined maintenance program keeps motors running cool, smooth, and efficient.

Measuring Results And ROI: Improvement begins with measurement. Track input kW with a true power meter and log kWh over time to see how changes affect energy use. Where possible, estimate output power from torque and speed or infer it from process indicators like flow, pressure, or throughput. Verify operation near the optimal efficiency band by reviewing load profiles and adjusting controls. Calculate savings by comparing baseline and improved kWh against operating hours and energy rates, then assess ROI and total cost of ownership. Look beyond the motor to the entire motor driven system: trim pump impellers, reduce throttling, fix leaks, and minimize idle time. Use VFD features such as ramping, sleep functions, and smart feedback to avoid unnecessary run time. Document KPIs like efficiency, power factor, and temperature to sustain gains. With a system level view and consistent monitoring, you turn efficiency from a one time upgrade into an ongoing, compounding advantage.