Quiet Power: Techniques to Reduce Motor Noise and Vibration

From balancing and alignment to PWM strategies and acoustic isolation, learn proven ways to cut motor noise and vibration at the source.

Understanding Motor Noise Sources

Quiet power begins with understanding where motor noise and vibration originate. Most issues trace back to a combination of source, path, and receiver factors. Mechanical contributors include imbalance, misalignment, looseness, gear mesh, belt resonance, and bearing defects. Electrical contributors show up as torque ripple, cogging, slot harmonics, and magnetostriction in stator laminations. Noise can be structure-borne through mounts and frames or airborne from fans and radiating panels. The real amplifier is resonance: when a forcing frequency, such as rotational speed or blade-pass frequency, nears a natural frequency, small inputs produce large responses. A practical approach is to reduce excitation at the source, interrupt transmission paths with isolation or damping, and treat radiating surfaces if needed. Because signatures change with speed and load, diagnostics should consider operating envelopes rather than a single point. By mapping dominant orders and harmonics, you can target interventions that yield the greatest reduction in overall NVH (noise, vibration, and harshness) without sacrificing motor performance or reliability.

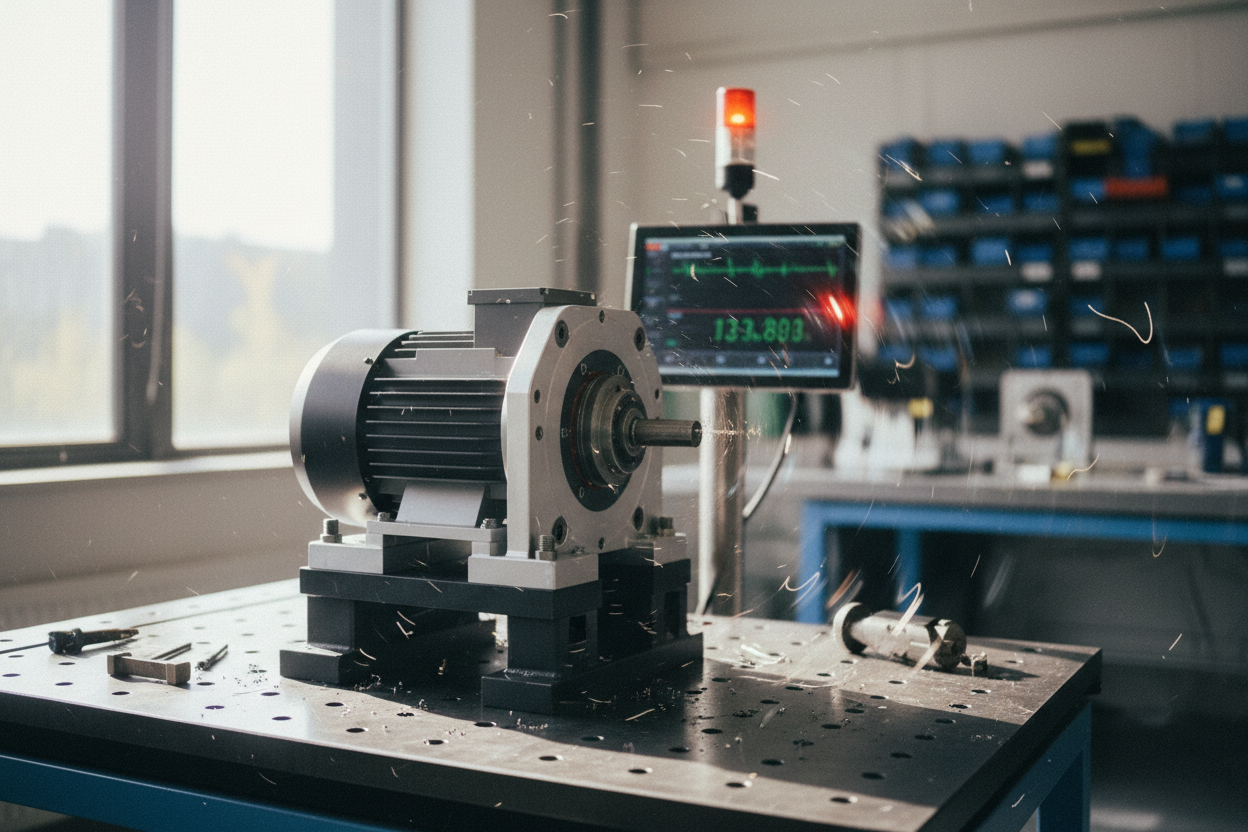

Balancing and Alignment Essentials

Effective balancing and alignment cut noise at its origin. Start with precision runout checks to distinguish eccentricity from true unbalance. Perform static and, where appropriate, two-plane dynamic balancing to control 1X and higher-order responses. For large rotors or installed equipment, trim balancing in situ often delivers excellent results with minimal downtime. On the alignment side, correct angular and offset errors using laser alignment or dial indicators, accounting for thermal growth so shafts remain coaxial at operating temperature. Eliminate soft foot by properly shimming and verifying uniform foot contact; otherwise, frame distortion reintroduces misalignment under bolt preload. Choose couplings that match misalignment and torsional needs—grid, disc, or elastomeric types each filter vibration differently. After adjustments, verify reduced 1X amplitude, stable phase, and lower bearing loads. Document shim stacks, torque values, and measured tolerances so future maintenance preserves the improved state. Meticulous setup here prevents downstream issues in bearings, seals, and foundations that otherwise radiate as objectionable noise.

Isolation, Damping, and Foundations

When transmission paths dominate, prioritize isolation and damping. Select elastomer mounts or spring isolators so the system's natural frequency sits well below the lowest excitation; this improves the transmissibility ratio and cuts structure-borne energy. Use snubbers or limit stops where shock loads exist, and consider seismic restraints for safety without short-circuiting isolation. A rigid, heavy inertia block with quality grout reduces base motion, while properly torqued anchors avoid bypassing isolators. Apply constrained-layer damping to guards, panels, and thin covers to tame ringing and reduce airborne radiation; even small patches at antinodes can yield big gains. For ducts and plenums, incorporate acoustic lining and decouple attachments to prevent re-radiation. Verify that cable trays, piping, and conduits do not bridge isolation points. On belt-driven systems, align sheaves and optimize belt tension to prevent whine and side forces. Finally, place mounts to balance center of gravity and consider horizontal as well as vertical stiffness to control rocking modes and yaw.

Electrical Strategies for Quieter Drives

Electrical refinement can dramatically lower tonal components. With VFD control, optimize PWM strategy and carrier frequency to move tones away from sensitive bands, while managing thermal and switching losses. Add sine filters or dv/dt filters to smooth waveforms and cut electromagnetic forces that excite laminations and end windings. Implement field-oriented control or advanced modulation to reduce torque ripple, especially at low speed where ripple is most perceptible. Address bearing currents by using shaft grounding and, where needed, insulated bearings to prevent electrical fluting that grows into audible roughness. For permanent-magnet machines, reduce cogging via current profiling and slight skew effects if design permits; for induction motors, ensure supply balance to avoid negative-sequence forces. Route and shield motor leads to minimize unintended coupling into structures and sensors. Finally, tune acceleration ramps and jerk limits to avoid exciting resonances during starts and stops, keeping transient noise brief and less intrusive without sacrificing control precision.

Bearings, Lubrication, and Clearances

The quietest motors rely on healthy bearings, correct clearances, and disciplined lubrication. Specify proper fits and preload so rolling elements run true without excessive heat. Choose a lubricant with the right viscosity and additive package to maintain film thickness under expected loads and temperatures; low-noise greases with fine base oils and compatible thickeners often outperform generic options. Avoid over-greasing, which causes churning, heat, and hiss-like noise; equally, under-greasing invites metal-to-metal contact and tonal growl. Maintain cleanliness—contamination drives early wear that rapidly becomes audible. Verify seal types: labyrinth designs reduce drag and noise, while contact seals need careful selection to balance protection and friction. Set axial endplay and air-gap uniformity to prevent rubs and electromagnetic unbalance. Check belt and coupling tension, fastener torque, and guard fit to eliminate buzz and rattle. When gears or fans are present, refine microgeometry and blade pitch to reduce mesh and blade-pass tones without compromising efficiency.

Testing, Commissioning, and Upkeep

Quiet performance is sustained through thoughtful testing and proactive maintenance. Begin with baseline FFT and order tracking across operating speeds to fingerprint dominant tones. Use a tachometer for synchronous averaging, and monitor 1X, 2X, bearing fault bands, and gear mesh lines. Conduct operational deflection shape or simple bump tests to reveal resonances; apply targeted damping or stiffness changes and then re-verify. During commissioning, create a repeatable checklist: alignment results, mount data, torque logs, and filter settings. Establish trend limits for overall vibration, peak amplitude, and crest factor so subtle degradations trigger investigation before noise escalates. Integrate condition monitoring with route-based or continuous sensors on critical assets. After any modification—new belts, rewinds, or control updates—retest to confirm the acoustic signature remains acceptable. Train technicians to recognize tonal patterns, document findings clearly, and schedule corrective actions. With disciplined feedback loops, your motor systems deliver durable, low-noise operation while preserving efficiency and uptime.