Waterproofing and Sealing Motors for Harsh Environments

Learn proven strategies to waterproof and seal motors for harsh environments, from IP ratings and gaskets to potting, coatings, cable glands, and testing.

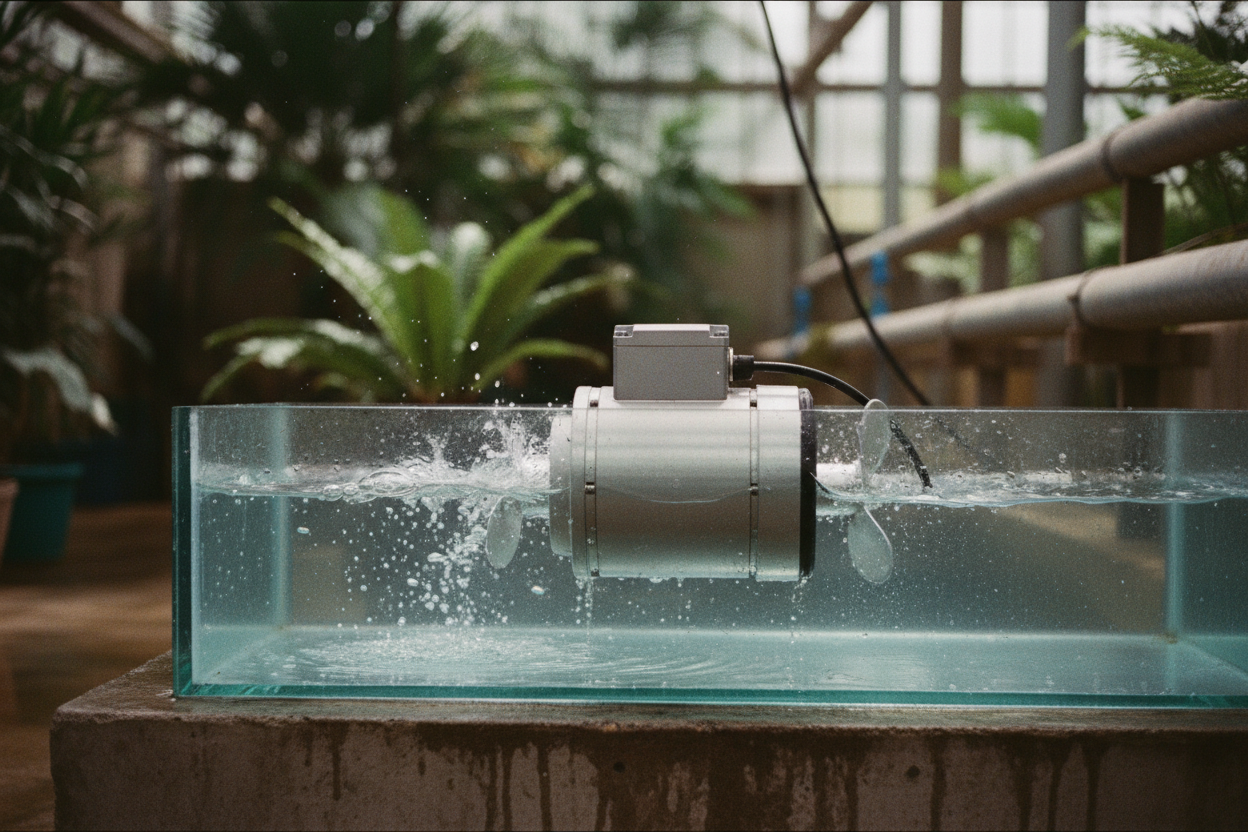

Why Motors Need Waterproofing

Motors operating in harsh environments face relentless threats from water, dust, mud, chemicals, and airborne salts that infiltrate housings and degrade performance. Moisture can wick along cables, creep through split lines, and enter at the shaft, end bells, and fasteners, attacking windings, bearings, and sensors. Without robust ingress protection, condensation and spray can trigger short circuits, reduce insulation resistance, and accelerate corrosion, while abrasive particles chew into seals and bearing races. Understanding where and how contaminants enter is the first step: cable entries, conduit threads, inspection covers, and casting porosity are common pathways. Selecting an appropriate IP rating sets a target, but execution matters more than labels; a well-integrated sealing strategy often outperforms ad hoc fixes. For AC induction, BLDC, servo, and stepper motors alike, protecting internal laminations, magnetics, and electronics extends uptime and stabilizes efficiency. Waterproofing is not just about blocking water; it is about controlling pressure cycles, eliminating capillary routes, and ensuring compatible materials. Done correctly, sealing prevents latent failures that appear long after installation, keeping critical motion systems dependable when exposure is routine rather than exceptional.

Proven Sealing Strategies

Effective waterproofing pairs layered defenses with careful interfaces. Start with precision-machined split lines and compressible gaskets sized for proper squeeze, adding O-rings or profile seals in dedicated grooves to control compression set. At the rotating interface, choose shaft seals—from standard lip seals with dust lips to mechanical seals for higher pressures—or labyrinth seals where low friction and debris shedding are priorities. For electrical penetrations, use rated cable glands with strain relief and sealing inserts matched to jacket diameter; pot unused entries. Inside the terminal box, apply potting or conformal coating on sensitive electronics, and seal cover threads with thread sealant or bonded washers. Consider encapsulation for static sensors and connectors, while keeping serviceable components accessible. Avoid flat, unsupported gaskets near bolt holes that can extrude under torque; use load-spreading ribs or metal carriers. Add drip shields and orientation features that steer runoff away from seals. Redundancy matters: pair primary barriers with secondary traps that end capillary action. Finally, validate the combined system against the targeted IP rating, not just individual parts, to prevent the weakest joint from defining the outcome.

Material Choices That Matter

Material compatibility underpins sealing durability. Elastomer selection should reflect media exposure: NBR or HNBR resist oils and fuels; FKM handles high temperatures and aggressive chemicals; EPDM excels with water and steam; silicone retains flexibility across broad temperatures but may swell in oils. For potting and coatings, choose epoxy for rigidity and chemical resistance, polyurethane for impact tolerance, or silicone RTV where thermal cycling is severe. Housing and hardware choices influence galvanic corrosion; pair stainless steel fasteners with compatible inserts, use anodized aluminum or protective nickel finishes, and add isolation washers when dissimilar metals must contact. Exterior finishes like powder coating, e-coat, or ceramic-filled epoxies extend life under UV, salt, and abrasion. For vents and membranes, hydrophobic ePTFE balances airflow with liquid blocking. Cable jackets in TPU, CPE, or chlorinated rubber withstand washdown and chemicals better than basic PVC. Always align hardness, rebound, and compression set of sealing elements with the joint design and torque range. Choosing materials by exposure profile, not just availability, yields seals that remain elastic, adherent, and leak-free long after installation.

Balancing Sealing with Heat and Condensation

Sealing a motor changes how it breathes and sheds heat. A fully encapsulated or tightly gasketed enclosure can trap warmth, elevating winding and bearing temperatures and shortening insulation life if unmanaged. Design for thermal management with heat-spreading endbells, external fins, and thermally conductive potting or pads that create low-resistance paths from hot spots to the housing. Consider higher-temperature greases and insulations when duty cycles run near the thermal limit. Moisture is not only an external risk; condensation forms when temperature swings draw humid air into cool cavities. Add pressure-equalization vents with hydrophobic membranes to minimize vacuum-driven ingress, and place them to avoid direct spray. Use desiccant in terminal compartments where service access breaks the seal. In applications demanding submersion, prioritize static seals and minimize penetrations, or incorporate controlled drains for designs targeting moderate IP levels. Mind vibration: micro-movement can pump seals and loosen glands, so apply locking features, adhesive patch fasteners, and anti-rotation details. A balanced approach treats sealing, heat flow, and pressure cycling as a single system so protection does not create new failure modes.

Installation, Testing, and Upkeep

Even the best design fails with poor assembly. Prepare surfaces by cleaning, drying, and lightly abrading if specified; apply primer for adhesives and cure sealants under recommended conditions. Compress gaskets to target squeeze using a cross-pattern torque sequence, and recheck after initial relaxation. Route cables with drip loops, respect bend radii, and tighten gland nuts to the manufacturer's range without twisting the jacket. Seal unused ports, cap connectors, and record torque values for traceability. Validate integrity with leak testing—air pressure decay or vacuum hold—followed by functional spray or submersion checks at the intended IP rating. Verify electrical health with insulation resistance and dielectric withstand tests after exposure. In service, schedule inspections to look for chalking, rust bloom, weeping at split lines, or swollen elastomers. Replace O-rings and lip seals proactively, refresh desiccants, and confirm fastener torque after thermal cycling. Clean using compatible detergents, angling washdown to avoid direct jets at vents and seals. A disciplined installation and maintenance program cements long-term waterproofing performance for critical motors.